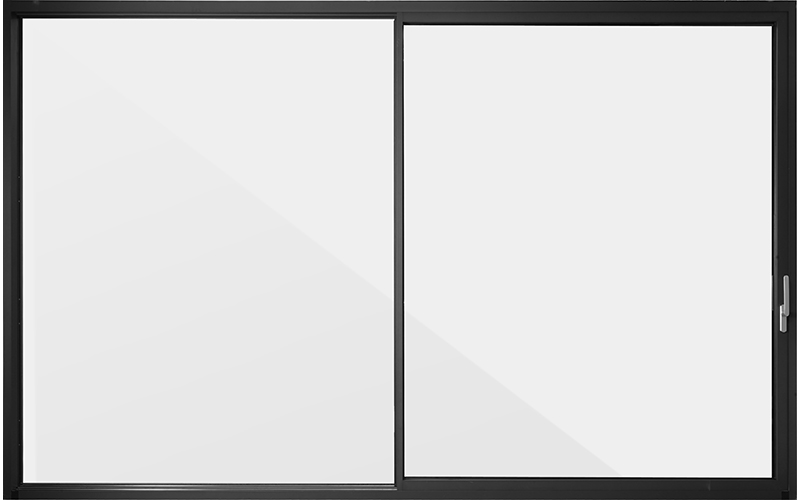

Best High Quality Sliding Room Door Manufacturers - Slim Lift & Slide System – MEDO

Best High Quality Sliding Room Door Manufacturers - Slim Lift & Slide System – MEDO Detail:

MDTSM 140 – 300KG

Profile wall thickness: 2.5mm

Frame size: 140mm

Glass thickness: 46mm

Max load: 300kg

Interlock size: 32mm

MDTSM 190 – 600KG

Profile wall thickness: 3.0mm

Frame size: 190mm

Glass thickness: 46mm

Max load: 600kg

Interlock size: 32mm

Aesthetics

Space becomes outstanding when it contains the noble concept of human settlements. MEDO believes that the discovery of the unique aesthetics of simplicity is based on exquisite details and excellent workmanship. The product is to meet different people’s aspirations for quality life and pursuit offorefront aesthetics.

MD-190TM

Slimline Lift And Slide Door System

How to apply slimline lift and slide door to the building is a real kind of tangle. How to ensure strong wind pressure resistance, heavy load bearing, water tightness, airtightness… all those are the issues that MEDO designers need to solve.

lt is an extreme challenge to make the sliding doors huge in size, slim with beautiful lines, and excellent in performances!

3.0mm wall thickness, well balanced profile lines, double thermal break, heavy duty with max 50Okg load bearing: all of those reflect the designers outstanding ability on profile structure design and the ultimate pursuit of hardware solution.

Dual thermal break, clamping track

Dual thermal break structure design to achieve high thermal insulation performance. Lift and slide system with special sealing gaskets and low friction sealing strip to achieve high performance of air tightness, water tightness and thermal insulation. Dedicated balance wheel and clamping track to make windows and doors more stable.

Special drainage design, panoramic view

3 drainage solutions with special drainage end design and exterior drainage tank design to satisfy different scenarios with excellent water tightness. Strengthened slim interlock design for large size panoramic sliding door with unlimited view.

High load bearing, 2-Track/Panel, 2-Lock/Panel

Heavy duty bottom roller and 2 tracks per sash to reach max 600kg for large panoramic panels. Double lock per panel for extraordinary safety and burglary proof.

Home application

Motorized operation for smart home. Heavy duty bottom roller for large panoramic panels. Lift and slide system provides excellent sealing for exterior doors. Configuration with lock for extra safety and privacy.

Dual thermal break structure and clamping track

Dual thermal break structure design to achieve high thermal insulation performance. Lift and slide system with special sealing gaskets and low friction sealing strip to achieve high performance of air tightness, water tightness and thermal insulation. Dedicated balance wheel and clamping track to make windows and doors more stable.

High low track, panoramic view

High low track design for excellent water tightness. Slim interlock for panoramic view.

Single fan open and close, High load bearing

Single opening panel to meet the function need of special scenario. Heavy duty bottom roller for big opening with unlimited view.

Home application

Lift and slide system for excellent exterior door sealing. Cylinder configuration for extra safety and privacy.

Improved Forced Entry Resistance

When a lift and slide door is shut and the handle is moved into the closed position, not only are the locking mechanisms engaged, but the full weight of the vent is set down onto the frame. Intruders would not only need to create enough leverage to break the multi point locking mechanism, but also move the weight of the vent.

In addition, even if the vent is left slightly open for ventilation, it cannot be just pushed open as long as the handle can’t be moved from the outside.

Better Water Tightness | Better Air Tightness | Increased Longevity

The lift and slide door utilizes a mechanism that lifts up the panel before sliding to avoid the commons issues of regular sliding doors and provides much better performances in water tightness and air tightness. First, it allows the seals to disengage and avoid any exposure to friction during operation; Second, thicker sealants can be applied since they do not add to the effort of opening the panel.

What’s more, lifespan is increased as the seals are not exposed to wear and damage from the friction.

Easy & Ultra Smooth Operation

MEDO Lift and Slide Systems allow the user to open even over-sized panels with a gentle push of a finger.

In addition to the lifted panel protected from the damage resulted by dust and small stones in the track,

MEDO Lift and Slide Doors use premium high-performance roller bearings to enhance smooth operation.

Thus, lift and slide door is highly recommended for large panels with heavy weight.

With easy-to-use handle and patented transmission mechanism, even children and elders can easily lift a heavy panel.

The simple turning motion not only unlocks the door but also lifts the door at the same time.

There is no additional finger-operated locking mechanism needed, and it will not get jammed over time.

Product detail pictures:

Related Product Guide:

Along with the "Client-Oriented" enterprise philosophy, a rigorous high-quality control process, superior production products along with a robust R&D group, we constantly deliver premium quality products, exceptional solutions and aggressive costs for Best High Quality Sliding Room Door Manufacturers - Slim Lift & Slide System – MEDO , The product will supply to all over the world, such as: Detroit, Peru, kazan, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.